|

Chongqing YongPu Thermoelectric Boiler Auxiliary Equipment Manufacturing Co., Ltd

|

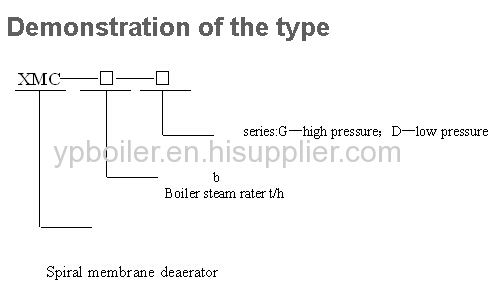

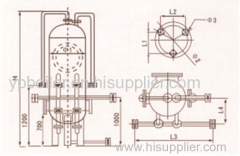

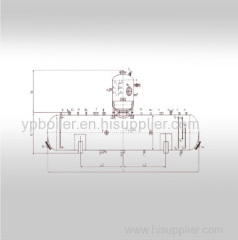

Spiral membrane deaerator of boiler

| Price: | 5800.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Chongqing, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

This equipment is on the basis of the original film type deaerator, developed by combining foreign advanced theory of oxygen,

This equipment is on the basis of the original film type deaerator, developed by combining foreign advanced theory of oxygen, the engineering and technical personnel for many years studying practice developed using depth deaerating device instead of traditional filling families, a new type of heat oxygen spin membrane oxygen.

Features

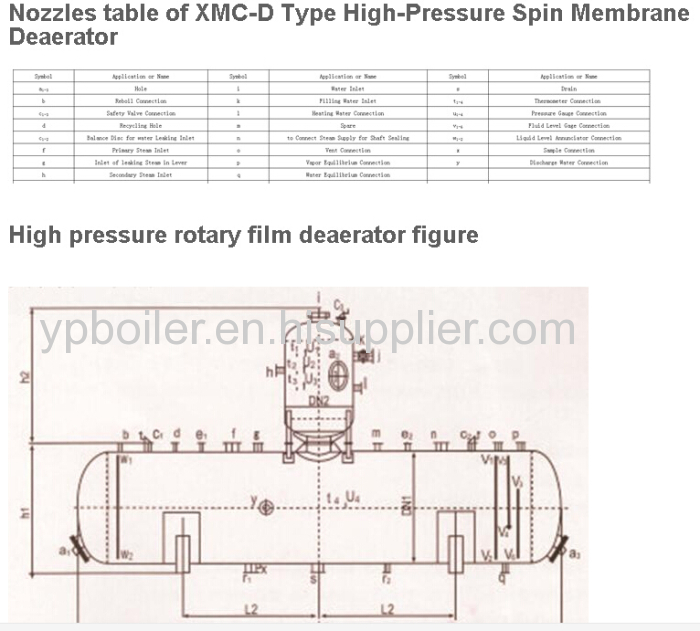

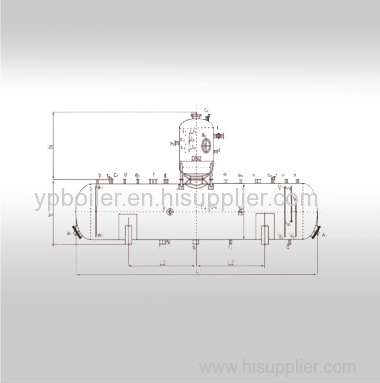

Spiral membrane deaerator is composed of oxygen removal tower and water tank of two parts.Water supply oxygen and heat deaerating device mainly in depth and the tower of oxygen to complete.Water tank for water oxygen, buffer and depth, and also when the boiler water preheating and insures the safe running of the feed water pump of the auxiliary function.(1) water within the deaerating head spray mist, use of continuous blowdown flash tank (or other)

secondary steam heating, this is the first level deaerating heating.(2) the secondary deaerating component membrane tube is the main components of heat mass transfer, need

according to the design and arrangement of the parameter selection number and process structures (3) has in oxygen Canon of the collector head into the depth of deaerating device (the device for the company at the heart of the new type of thermal deaerator technology) using hydrodynamic in depth deaerating device inside the water into water film layers, using a steam power break water membrane increase of dissolved oxygen water molecular kinetic energy, shorten the escaping time, dissolved oxygen use to steam heating heat of lower tertiary, lower oxygen solubility.

The depth of the deaerating effect is high

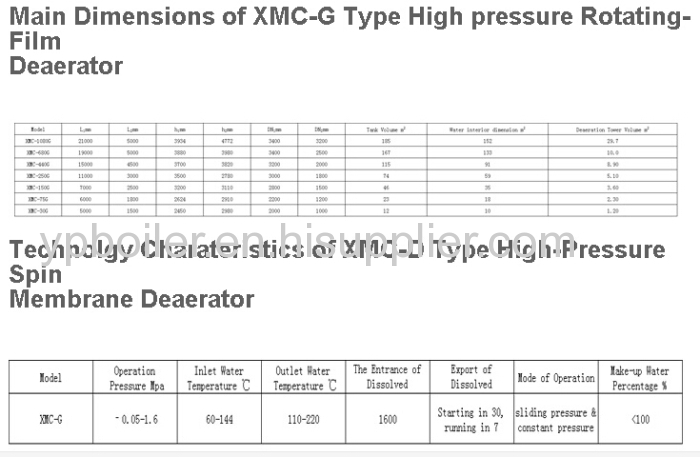

Oxygen water oxygen levels in the unit is started for 30 mu g/L, or less completely accord with the requirement of the soda power plant water vapor quality standards, and has achieved the international use of the specified value.Strong practicability applicable to the inlet water soluble oxygen (low voltage type 10000 mu g/L or less; high pressure type 2000 mu g/L)or less inlet water temperature is low (low voltage type: 13 ℃; high pressure type 60 ℃) change of pressure (low pressure type: - 0.0020.002 MPa;

high pressure type: - 0.05160 MPa) under the condition of running, operation mode can be used for sliding pressure and constant pressure or negative pressure operation.Stability is good When 25% load mutation, moment to supplement water 10%, when the switch to low temperature air supply, when the inlet water temperature in addition to significantly lower, the deaeration water can still be qualified, and deaerator vibration anomalies such as will not occur.energy conservationGas displacement is small, less than other types with the output of the deaerator 1/2 1/3, do not need to add the exhaust cooler, simplifies the system, reduces the heat loss.Pour water density is big, can reach 180 ㎡ / ㎡. H.Due to small size, and compared with the output of other types of deaerator can save a lot of steel, thus reducing the equipment material cost.It can be used in the sliding pressure and constant voltage operation, when the sliding pressure operation, can reduce heat loss value 4 kcal/kw. H.A 200 mw grade machine can save 800 tons of standard coal.